Deswik v4.0.1416.29157

Deswik Mining Consultants is an international company offering innovative mining engineering and geology services. We also produce cutting edge mine planning software by merging technical mining domain skills from each sector, with specialist programming expertise and the latest software development technologies. Our consulting acts as R&D for our software, and our software gives our consultants and clients a competitive edge. The company was formed in 2008, by the founders of African Computer Mining Services Pty Ltd (ACMS) who originally developed the popular Mine2-4D mine planning software. Deswik was also involved in minerals processing, however this part of the business has since been sold. Though Deswik is a relatively young company, our heritage of almost 20 years of delivering mine planning software solutions means that we have come a long way in a short period of time ... and we've only just begun. Our culture of high performance and innovation will ensure we remain a formidable force in the industry for a long time to come.

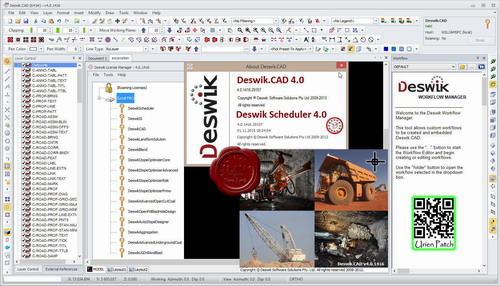

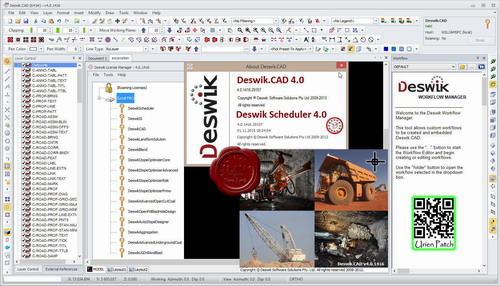

Deswik.CAD has been designed by mining engineers with decades of professional software development experience and a proven history of building technical mining applications. Programmed in the latest technologies to take advantage of high performance and cutting-edge computing developments, Deswik.CAD provides the user with a simple, modern and intuitive CAD-style interface. Deswik.CAD is effectively a spatial database combining the power of CAD with the ability to attribute, filter and report data visually and in tabular format. The file format is XML, so all data is open and transferable to other systems. Deswik.CAD is used across all mining sectors and is used in underground and open pit mines, both coal and metal, throughout the world. A list of all available modules and their functionality is outlined below.

Deswik.Scheduler. From interactive Gantt charts to PERT network diagrams, Deswik Scheduler is tailored for the needs of open pit or underground mine planners and can handle massive data sets while remaining responsive. For project managers, Deswik Scheduler provides Work Breakdown Structures and detailed Critical and Point to Point path analysis. Create detailed shift calendars for long term down to shift by shift scheduling or import your time usage model. Deswik Scheduler directly integrates with Deswik.CAD and the Deswik Interactive Scheduler to allow simple updating of mining task information from the graphics. Deswik Scheduler can import and import schedules from most of the popular scheduling packages including Microsoft Project, Primavera, and EPS.

The Deswik Landform and Haulage solution has the power, flexibility and ease of use to enable all engineers to answer questions which have hitherto been very difficult to answer. How many trucks do I require? What is the best truck to apply to my mining geometry? Is in-pit crushing and conveying more economical than a traditional truck haul? How does my fixed fleet affect my mining schedule and shovel productivities? What is the incremental value of adding a truck to my current fleet? Traditionally haulage has been performed by taking centroids from mining and dumping locations and manually calculating cycle times. Due to the manual nature of the process, only a handful cycletimes are practically possible and larger data sets are consequently used. Deswik has found that this can result in up to a 20% margin of error and, in addition, few options can be explored which leads to sub-optimal planning outcomes. The Deswik Landform and Haulage solution has the power, flexibility and ease of use to enable all engineers to answer questions which have hitherto been very difficult to answer. How many trucks do I require?

Deswik.CAD has been designed by mining engineers with decades of professional software development experience and a proven history of building technical mining applications. Programmed in the latest technologies to take advantage of high performance and cutting-edge computing developments, Deswik.CAD provides the user with a simple, modern and intuitive CAD-style interface. Deswik.CAD is effectively a spatial database combining the power of CAD with the ability to attribute, filter and report data visually and in tabular format. The file format is XML, so all data is open and transferable to other systems. Deswik.CAD is used across all mining sectors and is used in underground and open pit mines, both coal and metal, throughout the world. A list of all available modules and their functionality is outlined below.

Deswik.Scheduler. From interactive Gantt charts to PERT network diagrams, Deswik Scheduler is tailored for the needs of open pit or underground mine planners and can handle massive data sets while remaining responsive. For project managers, Deswik Scheduler provides Work Breakdown Structures and detailed Critical and Point to Point path analysis. Create detailed shift calendars for long term down to shift by shift scheduling or import your time usage model. Deswik Scheduler directly integrates with Deswik.CAD and the Deswik Interactive Scheduler to allow simple updating of mining task information from the graphics. Deswik Scheduler can import and import schedules from most of the popular scheduling packages including Microsoft Project, Primavera, and EPS.

The Deswik Landform and Haulage solution has the power, flexibility and ease of use to enable all engineers to answer questions which have hitherto been very difficult to answer. How many trucks do I require? What is the best truck to apply to my mining geometry? Is in-pit crushing and conveying more economical than a traditional truck haul? How does my fixed fleet affect my mining schedule and shovel productivities? What is the incremental value of adding a truck to my current fleet? Traditionally haulage has been performed by taking centroids from mining and dumping locations and manually calculating cycle times. Due to the manual nature of the process, only a handful cycletimes are practically possible and larger data sets are consequently used. Deswik has found that this can result in up to a 20% margin of error and, in addition, few options can be explored which leads to sub-optimal planning outcomes. The Deswik Landform and Haulage solution has the power, flexibility and ease of use to enable all engineers to answer questions which have hitherto been very difficult to answer. How many trucks do I require?