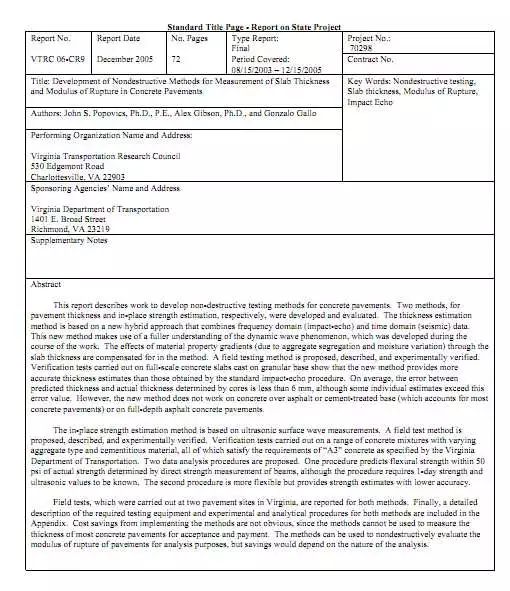

Development of Nondistructive Methods for Measurement of Slab Thickness and Madulus of Rupture in Concrete Pavements

FINAL CONTRACT REPORT

DEVELOPMENT OF NONDESTRUCTIVE METHODS FOR MEASUREMENT OF SLAB THICKNESS AND MODULUS OF RUPTURE IN CONCRETE PAVEMENTS

John S. Popovics, Ph.D., P.E. Assistant Professor of CEE

Alex Gibson, Ph.D.

Graduate Research Assistant

Gonzalo Gallo Graduate Research Assistant

University of Illinois at Urbana-Champaign

Project Manager David W. Mokarem, Ph.D., Virginia Transportation Research Council

FINAL CONTRACT REPORT

DEVELOPMENT OF NONDESTRUCTIVE METHODS FOR MEASUREMENT OF SLAB THICKNESS AND MODULUS OF RUPTURE IN CONCRETE PAVEMENTS

John, S. Popovics, Ph.D., P.E.

Assistant Professor of CEE University of Illinois at Urbana-Champaign

Alex Gibson, Ph.D.

Graduate Research Assistant University of Illinois at Urbana-Champaign

Gonzalo Gallo

Graduate Research Assistant University of Illinois at Urbana-Champaign

INTRODUCTION

For a new portland cement concrete (PCC) pavement to reach its designed service life, it must be designed and built with a proper combination of adequate slab thickness and in-place strength, both of which are selected for the traffic load that the pavement is expected to bear. Therefore, as part of the quality control/assurance (QA/QC) process, it is essential for every newly constructed PCC pavement to be inspected soon after construction is completed (within 28 days) to verify that the contractor has complied with specifications on thickness and strength of the concrete slab. In order to apply an effective QA/QC process the pavement properties (thickness and strength) must be determined with a certain level of accuracy. In a recent study on performance-related specifications, Graveen (2001) recommended that concrete pavement thickness be determined with an accuracy of ±6mm (±1/4 inch) and modulus of rupture with an accuracy of ±345 kPa (±50psi) in order to ensure reasonable and appropriate application of such QC/QA specifications. In fact, the Indiana Department of Transportation now uses those values in its performance-based specifications for concrete pavements (IDOT, 2005).

At present, such verification involves drilling or sawing samples from each newly

constructed concrete pavement so that the slab thickness and strength can be measured by prescribed standard methods. Since coring is time-consuming and leaves undesirable discontinuities in a pavement, there is reluctance in carrying out this inspection in a statistically thorough manner. There is, therefore, a need for rapid and nondestructive alternative methods that can be used in place of coring. With such nondestructive evaluation (NDE) methods, the inspection can be conducted at more sampling locations on a pavement for improved pavement quality assurance testing.

Download

http://s18.alxa.net/s18/srvs2/01/De...ve.Methods.rar