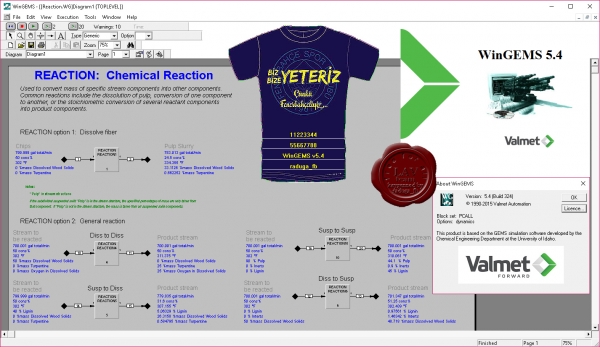

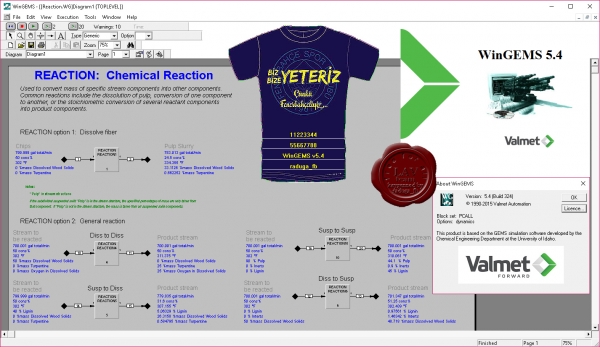

Valmet (ex. Metso) WinGEMS v5.4.324

WinGEMS is the Pulp&Paper industry's premier process simulation tool that combines the ease of use of a graphical interface with twenty-five plus years of experience and process knowledge contained in the GEMS modular simulator. Application of WinGEMS can be used to perform mill financial modeling, steam plant optimization, VOC emission prediction, full mill process simulation, and steam monitoring to name a few. WinGEMS is very user friendly and easily communicates with an Excel spreadsheet.

With new features, including over 75 new pre-built process unit blocks, Valmet WinGEMS can save days in the development of a full mill simulation. These blocks contain a wealth of knowledge and experience to assist in modeling all areas of the pulp and paper making process.

Benefits:

Supports faster and more accurate planning and decision-making

Provides a common basis for evaluating proposed process changes

Allows quick assessment of operation and capital planning scenarios that can’t be tested in a real-world situation

Allows plant designs to be "operations tested” during the design phase, avoiding costly design errors

Helps eliminate costs associated with over/under capacity

Enhances understanding of the "big picture” through better understanding of process relationships, bottlenecks, and interactions

Provides savings in time and materials with ongoing daily troubleshooting and equipment evaluation capabilities

43.2MB

http://s15.alxa.net/001/01/Metso.WinGEMS.v5.4.324.rar

WinGEMS is the Pulp&Paper industry's premier process simulation tool that combines the ease of use of a graphical interface with twenty-five plus years of experience and process knowledge contained in the GEMS modular simulator. Application of WinGEMS can be used to perform mill financial modeling, steam plant optimization, VOC emission prediction, full mill process simulation, and steam monitoring to name a few. WinGEMS is very user friendly and easily communicates with an Excel spreadsheet.

With new features, including over 75 new pre-built process unit blocks, Valmet WinGEMS can save days in the development of a full mill simulation. These blocks contain a wealth of knowledge and experience to assist in modeling all areas of the pulp and paper making process.

Benefits:

Supports faster and more accurate planning and decision-making

Provides a common basis for evaluating proposed process changes

Allows quick assessment of operation and capital planning scenarios that can’t be tested in a real-world situation

Allows plant designs to be "operations tested” during the design phase, avoiding costly design errors

Helps eliminate costs associated with over/under capacity

Enhances understanding of the "big picture” through better understanding of process relationships, bottlenecks, and interactions

Provides savings in time and materials with ongoing daily troubleshooting and equipment evaluation capabilities

43.2MB

http://s15.alxa.net/001/01/Metso.WinGEMS.v5.4.324.rar