Process Systems Enterprise gPROMS v3.6

gPROMS is a platform for high-fidelity predictive

modelling for the process industries. Its main

applications are in model-based engineering

activities for process and equipment development and

design, and optimisation of process operations.

gPROMS is applied by major process and technology

organisations throughout the world, across many

application areas in all process sectors. It is also

used for research and teaching at 200 academic

institutions worldwide.

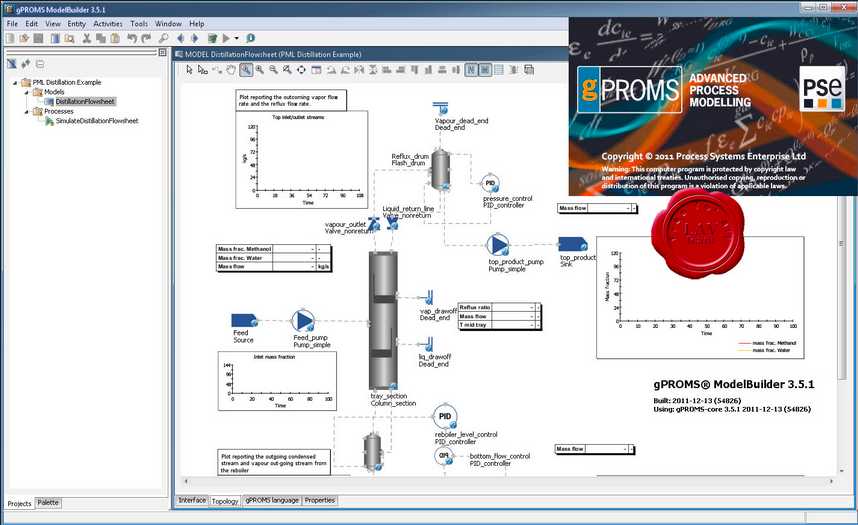

At the heart of the gPROMS platform is the gPROMS

ModelBuilder, the leading custom modelling

environment for the process industries.

ModelBuilder's process modelling, process simulation

and optimisation capabilities are used to generate

high-accuracy predictive information for decision

support in product and process innovation, design

and operation.

gPROMS platform products have many major advantages

over other comparable modelling software:

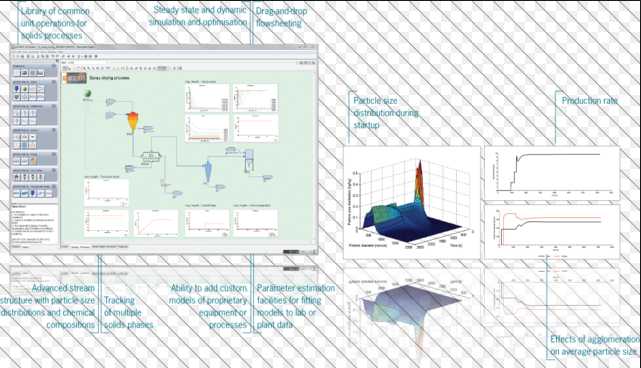

* Support for multiscale modelling, meaning - for

example - that it is possible to create a reactor

model that takes into account all phenomena from

mass transfer in the catalyst pore to full-scale

equipment effects simultaneously

* Custom modelling capabilities that allow the

development, execution and maintenance of

high-fidelity models of a wide range of equipment

* The abilty to apply such high-fidelity unit models

within a full process flowsheet

* Estimation of equipment or process empirical

parameters from experimental - laboratory, pilot

or operational - data, with estimates of data

uncertainty for risk analysis

* Steady-state and dynamic modelling within the same

environment

* The ability to perform many different activities

using the same underlying model

* Support for scale-up from minimal experimental

data to full equipment, using hybrid modelling

technologies where necessary.

gPROMS is an equation-oriented modelling system used

for building, validating and executing

first-principles models within a flowsheeting

framework.

Models are constructed in the gPROMS ModelBuilder by

writing down the fundamental chemistry, physics,

chemical engineering, operating procedures and other

relationships that govern the process or product

behaviour.

The resulting model is then validated against

observed data - typically, laboratory, pilot plant

or operating data - to adjust model parameters such

as heat transfer coefficients to match reality as

closely as possible.

Of course, it is not necessary to create a model

from scratch every time - you can use one of the

many state-of-the-art gPROMS model libraries, or

create your own library for publishing throughout

your organisation. Once a model exists, it can be

solved in many different ways to perform many

different activities - for example:

* Steady-state simulation, for example to optimise

steady-state process conditions

* Dynamic simulation, for example in control design

or design of operating procedures

* Parameter estimation, to determine empirical

parameters from real-life data

* Model-based experiment design, to design the

optimal next experiment to generate additional

data in areas of uncertainty

* Steady-state and dynamic optimisation, including

integer optimisation, for direct calculation (as

opposed to trial-and-error simulation) of

variables or trajectories of interest

* Generation of linearised models for use in control

and online optimisation

The activities can be applied at different stages

across the process lifecycle. This means that once

you have invested in creating an accurate gPROMS

model of your process you can use that model

wherever it can generate value, to ensure multiple

return on investment.

165MB

Download

http://s19.alxa.net/s8/srvs1/PSD/MAX/...racked-EAT.rar