Structural Strengthening with FRP

The strengthening or retrofitting of existing concrete structures to resist higher design loads, correct strength loss due to deterioration, correct design or construction deficiencies, or increase ductility has traditionally been accomplished

using conventional materials and construction techniques. Externally bonded steel plates, steel or concrete jackets, and external post-tensioning are just some of the many traditional techniques available.

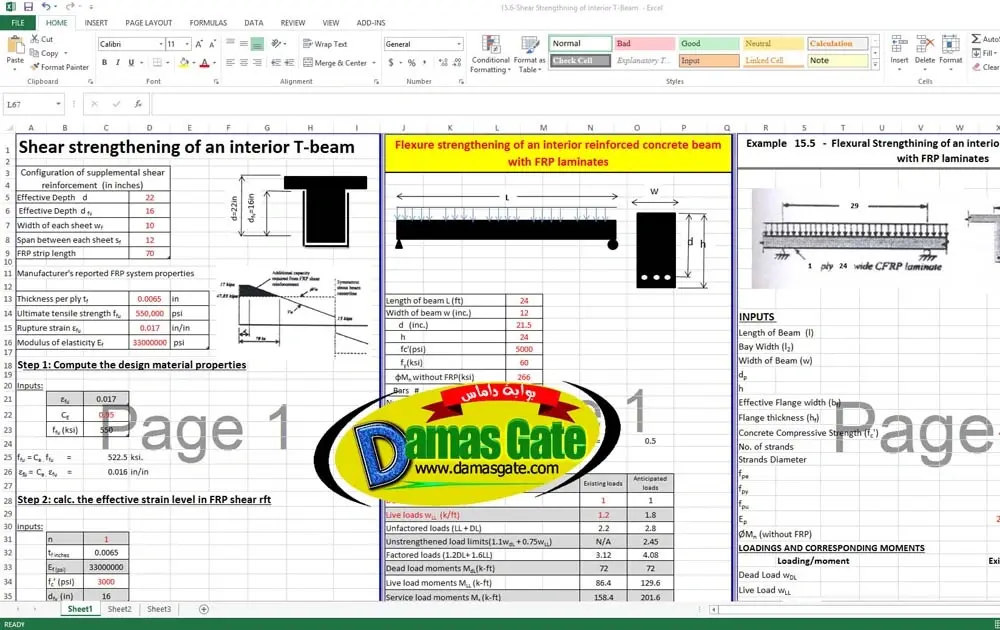

Composite materials made of fibers in a polymeric resin, also known as fiber-reinforced polymers (FRPs), have emerged as an alternative to traditional materials for repair and rehabilitation. For the purposes of this document, an FRP

system is defined as the fibers and resins used to create the composite laminate, all applicable resins used to bond it to the concrete substrate, and all applied coatings used to protect the constituent materials. Coatings used exclusively for aesthetic reasons are not considered part of an FRP system. FRP materials are lightweight, noncorrosive, and exhibit high tensile strength. These materials are readily available in several forms, ranging from factory-made laminates to dry fiber sheets that can be wrapped to conform to the geometry of a structure before adding the polymer resin. The relatively thin profiles of cured FRP systems are often desirable in applications where aesthetics or access is a concern. The growing interest in FRP systems for strengthening and etrofitting can be attributed to many factors. Although the fibers and resins used in FRP systems are relatively expensive compared with traditional strengthening materials such as concrete and steel, labor and equipment costs to install FRP systems are often lower (Nanni 1999). FRP systems can also be used in areas with limited access where traditional techniques would be difficult to implement.

using conventional materials and construction techniques. Externally bonded steel plates, steel or concrete jackets, and external post-tensioning are just some of the many traditional techniques available.

Composite materials made of fibers in a polymeric resin, also known as fiber-reinforced polymers (FRPs), have emerged as an alternative to traditional materials for repair and rehabilitation. For the purposes of this document, an FRP

system is defined as the fibers and resins used to create the composite laminate, all applicable resins used to bond it to the concrete substrate, and all applied coatings used to protect the constituent materials. Coatings used exclusively for aesthetic reasons are not considered part of an FRP system. FRP materials are lightweight, noncorrosive, and exhibit high tensile strength. These materials are readily available in several forms, ranging from factory-made laminates to dry fiber sheets that can be wrapped to conform to the geometry of a structure before adding the polymer resin. The relatively thin profiles of cured FRP systems are often desirable in applications where aesthetics or access is a concern. The growing interest in FRP systems for strengthening and etrofitting can be attributed to many factors. Although the fibers and resins used in FRP systems are relatively expensive compared with traditional strengthening materials such as concrete and steel, labor and equipment costs to install FRP systems are often lower (Nanni 1999). FRP systems can also be used in areas with limited access where traditional techniques would be difficult to implement.