SOLIDWORKS Simulation - Troubleshooting Common Errors

Duration 58m Project Files Included MP4

SOLIDWORKS Simulation – Troubleshooting Common Errors

Info:

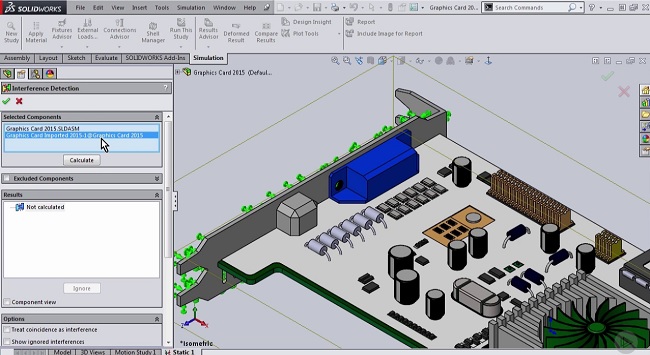

Designers and engineers primarily use structural simulation to determine the strength and stiffness of a product by reporting component stress and deformations. In this course, SOLIDWORKS Simulation – Troubleshooting Common Errors, you’ll learn how to modify geometry and learn techniques to prevent mesh failures, and to prevent other failures associated with mesh size. First, you’ll learn about fixing broken faces due to bad imports. Next, you’ll learn about mesh failures and about solver instability warnings. Then, you’ll learn about result accuracy questions and will learn about idealization errors. Finally, you’ll learn how to troubleshoot if your study will not completely solve, and how to trust and prove your conclusions numerically. By the end of this course, you’ll know how to prepare your model for simulation, modify it or the simulation if mesh failures occur. Software required: SOLIDWORKS 2016

Designers and engineers primarily use structural simulation to determine the strength and stiffness of a product by reporting component stress and deformations. In this course, SOLIDWORKS Simulation – Troubleshooting Common Errors, you’ll learn how to modify geometry and learn techniques to prevent mesh failures, and to prevent other failures associated with mesh size. First, you’ll learn about fixing broken faces due to bad imports. Next, you’ll learn about mesh failures and about solver instability warnings. Then, you’ll learn about result accuracy questions and will learn about idealization errors. Finally, you’ll learn how to troubleshoot if your study will not completely solve, and how to trust and prove your conclusions numerically. By the end of this course, you’ll know how to prepare your model for simulation, modify it or the simulation if mesh failures occur. Software required: SOLIDWORKS 2016