Mobatec Modeller v4.15192

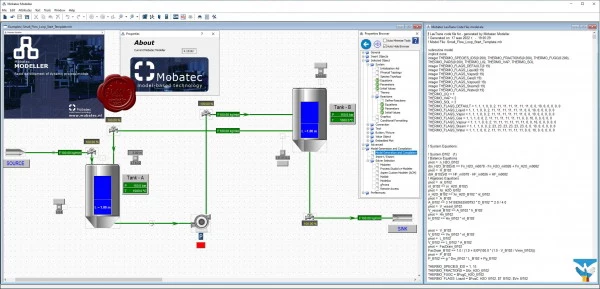

The process modelling methodology implemented in Mobatec Modeller is based on the hierarchical decomposition of processes into networks of elementary systems and physical connections. This process modelling software combines two approaches to modelling: equation based modelling and flowsheeting. This makes it an advanced process modelling software which is best described as an Equation Based Flowsheeter.

Equation based (white box) modelling is flexible, as users can create custom tailored models to their own needs resulting in a high fidelity simulations. Conventionally equation based modellers require a programming language, used by the user to transform (code) the model equations into lots of lines of code in order for solver to solve the model. This code is not transparent, and even experienced users need time to use, modify or improve existing models. With Mobatec Modeller no knowledge of code (programming) is required, equations are written almost as on paper and the code is generated automatically by the software.

Some of the things that give it an edge over other softwares:

Huge reduction of model developing time and overall effort.

No process modelling expert is needed to set up, modify, or even understand your process models.

Even beginning users can quickly setup complex models that are transparent for others.

Model builders don’t have to be computer programmers that need to worry on how to translate mathematical equations into a solvable computer syntax. Mobatec Modeller takes care of this. Mobatec Modeller makes modelling more accessible and fun.

The models are transparent and also easy to understand by users who were not involved with the model development.

Construct models of industrial, lab-scale or pilot plant processes (either continuous, semi-continuous, batch or semi-batch, either complete process or only parts).

Perform dynamic and realistic simulations of your chemical-physical processes with an outstanding 2D interface and easily connect to 3D interfaces and/or third party DCS software.

Compatible with other softwares, easy export function to any other modelling environment or software.

Size: 149 MB

Download

*

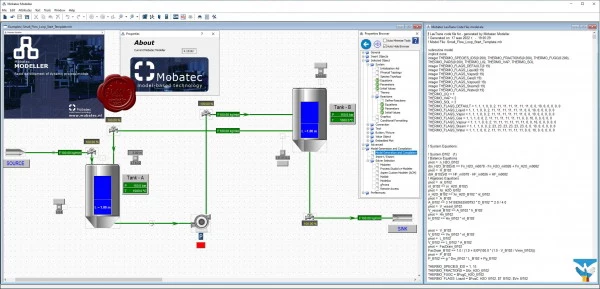

The process modelling methodology implemented in Mobatec Modeller is based on the hierarchical decomposition of processes into networks of elementary systems and physical connections. This process modelling software combines two approaches to modelling: equation based modelling and flowsheeting. This makes it an advanced process modelling software which is best described as an Equation Based Flowsheeter.

Equation based (white box) modelling is flexible, as users can create custom tailored models to their own needs resulting in a high fidelity simulations. Conventionally equation based modellers require a programming language, used by the user to transform (code) the model equations into lots of lines of code in order for solver to solve the model. This code is not transparent, and even experienced users need time to use, modify or improve existing models. With Mobatec Modeller no knowledge of code (programming) is required, equations are written almost as on paper and the code is generated automatically by the software.

Some of the things that give it an edge over other softwares:

Huge reduction of model developing time and overall effort.

No process modelling expert is needed to set up, modify, or even understand your process models.

Even beginning users can quickly setup complex models that are transparent for others.

Model builders don’t have to be computer programmers that need to worry on how to translate mathematical equations into a solvable computer syntax. Mobatec Modeller takes care of this. Mobatec Modeller makes modelling more accessible and fun.

The models are transparent and also easy to understand by users who were not involved with the model development.

Construct models of industrial, lab-scale or pilot plant processes (either continuous, semi-continuous, batch or semi-batch, either complete process or only parts).

Perform dynamic and realistic simulations of your chemical-physical processes with an outstanding 2D interface and easily connect to 3D interfaces and/or third party DCS software.

Compatible with other softwares, easy export function to any other modelling environment or software.

Size: 149 MB

Download

*