Basics of Plastics design for design engineers

Learn about the fundamentals of mechanical design with plastics in the design process

What you'll learn

What are different types of plastics and why they are useful

Mechanical behaviour of plastics

Creep phenomona and visco elastic behaviour

Plastics in Fatigue, Impact and hardness property

What are Reinforced plastics

Design process, parameters and factors to consider

Requirements

Basic background on plastics

Background on strength of materials

Description

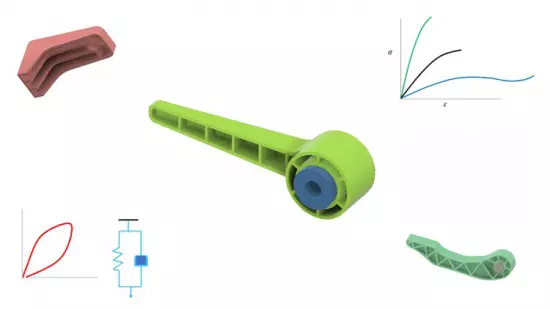

Plastics as a family of materials have been exceedingly used for product design .

Designing with the plastic materials is generally not so straightforward as steels and aluminum. Due to the dependency of material properties on various factors.

This course is an attempt to collate the important considerations when designing with plastic materials.

Topics covered

1. What are polymers and plastics

2. Difference between thermo plastics and Thermosets

3. Difference between amorphous and crystalline types

4. The advantages and disadvantages of using plastics for design

5. Importance of data and tests - Design approach

6. Mechanical behaviour - Stress strain diagram

7. Flexibility, rigidity, Ductile vs brittle behaviour, Linear and Non linear behaviour

8. Yield point and Elongation

9. Glass transition temperature and its importance

10. Visco elastic behaviour - Models

11. Phenomenon of Creep and how it takes place

12. Creep rupture definition

13. Behaviur in Fatigue and Fracture toughness compared to steel

14. Impact toughness and which plastics are superior compared to others?

15. Hardness property and its measurement , importance

16. Abrasion and Friction properties . Plastics which are good selection for anti friction applications

17. What are re-inforced plastics. Their impact and Anisotropy

18. Designing plastics within the larger Design process. Steps to consider, checks to include.

19. Material selection guide and factors to consider when selecting apt material

20. Dimensional stability, tolerances

21. Design for Injection molding

This course is designed to aid Design engineers in the Plastics product design activity. To go beyond CAD skills and develop holistic fundamental understanding of behaviour of plastics . Helping to make better material decisions and design decisions.

Who this course is for

Design engineers who want to design with plastics with confidence understanding fundamentals

Engineering students

Published 07/2022

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz, 2 Ch

Genre: eLearning | Language: English + srt | Duration: 44 lectures (4h 46m) | Size: 1.18 GB

Download

http://s6.alxa.net/one/2022/06/Basic....engineers.rar

Learn about the fundamentals of mechanical design with plastics in the design process

What you'll learn

What are different types of plastics and why they are useful

Mechanical behaviour of plastics

Creep phenomona and visco elastic behaviour

Plastics in Fatigue, Impact and hardness property

What are Reinforced plastics

Design process, parameters and factors to consider

Requirements

Basic background on plastics

Background on strength of materials

Description

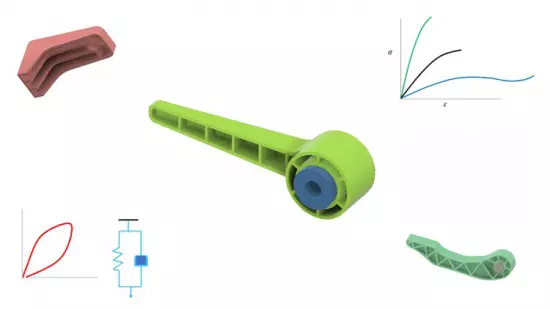

Plastics as a family of materials have been exceedingly used for product design .

Designing with the plastic materials is generally not so straightforward as steels and aluminum. Due to the dependency of material properties on various factors.

This course is an attempt to collate the important considerations when designing with plastic materials.

Topics covered

1. What are polymers and plastics

2. Difference between thermo plastics and Thermosets

3. Difference between amorphous and crystalline types

4. The advantages and disadvantages of using plastics for design

5. Importance of data and tests - Design approach

6. Mechanical behaviour - Stress strain diagram

7. Flexibility, rigidity, Ductile vs brittle behaviour, Linear and Non linear behaviour

8. Yield point and Elongation

9. Glass transition temperature and its importance

10. Visco elastic behaviour - Models

11. Phenomenon of Creep and how it takes place

12. Creep rupture definition

13. Behaviur in Fatigue and Fracture toughness compared to steel

14. Impact toughness and which plastics are superior compared to others?

15. Hardness property and its measurement , importance

16. Abrasion and Friction properties . Plastics which are good selection for anti friction applications

17. What are re-inforced plastics. Their impact and Anisotropy

18. Designing plastics within the larger Design process. Steps to consider, checks to include.

19. Material selection guide and factors to consider when selecting apt material

20. Dimensional stability, tolerances

21. Design for Injection molding

This course is designed to aid Design engineers in the Plastics product design activity. To go beyond CAD skills and develop holistic fundamental understanding of behaviour of plastics . Helping to make better material decisions and design decisions.

Who this course is for

Design engineers who want to design with plastics with confidence understanding fundamentals

Engineering students

Published 07/2022

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz, 2 Ch

Genre: eLearning | Language: English + srt | Duration: 44 lectures (4h 46m) | Size: 1.18 GB

Download

http://s6.alxa.net/one/2022/06/Basic....engineers.rar