Started With Siemens Nx Cam 2312 Hands On-Learn By Doing

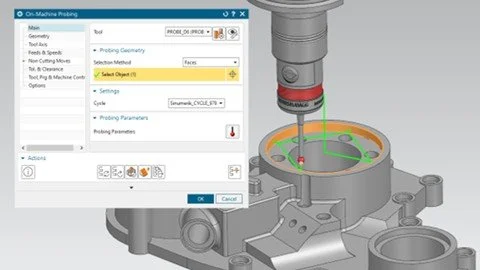

Siemens NX CAM Hands-On. Learn how to create toolpath and CNC Program using NX CAM for Beginners.

What you'll learn

You will understand CAM concept and advanced manufacturing topics in Siemens NX CAM 2312.

How to import the part file from any CAD software like Solidworks, Solidedge and catia v5.

Work independently on any Part in any version of Siemens NX .

Make any toolpath for any complex part easily using a NX CAM operations as shown in Examples.

Requirements

Any cad course knowledge.

Description

The SIEMENS NX CAM 2312 Basic Manufacturing course will introduce the main concepts of CAM programming using this computer-aided manufacturing tool. It will introduce the student to all the concepts and most importantly tools, the work philosophy within NX CAM 2312. In this course, several 2.5Axis, 3Axis, and 4Axis machining toolpath will be covered, where the student will learn to correctly choose and define their machining strategies, create tools, learn that, with NX 2312,In this course I will cover· Planner milling (generate complete machining processes for prismatic parts of any complexity)· Contour milling (generate high-quality mold inserts using a complete set of advanced NC programming tools.)· Multi axis (generate Advanced 3+2 milling and 5-axis machining methods allow you to produce challenging molds with deep cavities)· Turning (Generate program for 2D part profiles or full solid models roughing, multiple pass finishing, grooving, thread cutting and centerline drilling operations)· HOLE making (Generate program for 2D part or full solid models for Drilling, Spot drilling etc operations)· Features machining (NX CAM 2312 can automate CNC programing by using Feature-Based Machining (FBM)· Multi axis Blade (Generate programming of complex multi-bladed such as blisks and impellers)· Mill rotary (generate programming of complex rotational parts, with specialized 4-axis NC programming operations)· Post processor (Generate NC programs for a wide range of machine tools and controllers using Post builder)

Overview

Section 1: Introduction

Lecture 1 Introduction to NX CAM 2312

Lecture 2 How to import .xt, stp & .prt files

Lecture 3 How to define Blank Geometry for NX CAM

Lecture 4 Manufacturing Assemblies Introduction

Lecture 5 Non cutting Move (Engage & Retract)

Lecture 6 Cutting Parameters (Cut Level)

Lecture 7 Cutting Parameters 2

Lecture 8 NC Assistant

Lecture 9 How to add tool in tool library

Section 2: NX 2312 Milling Planar Milling (2.5 Axis Operations)

Lecture 10 FaceMill MidPass operation

Lecture 11 Face_Mill_ZigZag Operation

Lecture 12 Floor Facing without wall operation

Lecture 13 Floor and Wall Operation

Lecture 14 Pocket Milling Operation

Lecture 15 2D Profile wall without Floor

Lecture 16 2D Profile Wall with Floor

Lecture 17 Planar profile

Lecture 18 Planar profile

Lecture 19 Planar MIll

Lecture 20 Groove Milling

Lecture 21 Face mill Manual

Lecture 22 Planar Text

Lecture 23 2.5Axis Planar Mill

Section 3: NX 2312 Milling Contour Operations (3 Axis operations)

Lecture 24 Cavity Mill Rough operation

Lecture 25 Cavity Mill

Lecture 26 Cavity Mill

Lecture 27 Cavity Mill

Lecture 28 REST Mill

Lecture 29 Plunge mill Rough operation

Lecture 30 Z LEVEL PROFILE STEEP

Lecture 31 ZLEVEL PROFILE EXERCISE

Lecture 32 ZLevel Corner

Lecture 33 Quick Roughing

Lecture 34 3D Adaptive Roughing milling

Lecture 35 3D Adaptive Roughing milling

Lecture 36 3D Adaptive Roughing milling

Lecture 37 Area Mill Finishing operation

Lecture 38 Area Mill Finishing operation

Lecture 39 Area Mill Finishing operation

Lecture 40 Area Mill Finishing operation

Lecture 41 Fixed Axis Guiding Curve finishing operation

Lecture 42 Fixed Axis Guiding Curve finishing operation

Lecture 43 ZLevel UnderCut

Lecture 44 Flow Cut Drive method

Lecture 45 Curve drive operation

Lecture 46 Solid Profile operation

Lecture 47 Profile 3D operation

Lecture 48 Streamline Finishing operation

Lecture 49 Streamline Finishing operation

Lecture 50 Contour Surface Drive finishing operation

Lecture 51 Contour Surface Drive finishing operation

Lecture 52 contour Text Engraving operation

Lecture 53 3_AXIS_DEBURRING

Lecture 54 Multi setup toolpath (IPW Blank)

Section 4: NX 2312 Milling Cutting Parameters & Non-Cutting Moves

Lecture 55 Non-Cutting Move (Engage & Retract)

Lecture 56 Cutting Parameters (Cut Level)

Lecture 57 Cutting Parameters

Lecture 58 How to Trim toolpath and Divide toolpath

Lecture 59 How to transform toolpath

Lecture 60 Toolpath SUB Options (Toolpath check, Validity Report etc)

Lecture 61 How to create 3Axis post processer

Section 5: Hole machining operations

Lecture 62 Spot Drill & Drilling

Lecture 63 Deep Hole Drilling

Lecture 64 Hole milling

Lecture 65 Boss Milling

Lecture 66 Radial Groove Milling

Lecture 67 Hole chamfer mill

Section 6: NX 2312 Milling 3 Axis Projects

Lecture 68 Project 1

Lecture 69 Project 2

Lecture 70 Project 3

Lecture 71 Project Cavity

Section 7: Rotary MILL (4Axis Milling operations)

Lecture 72 TURN MILL Rough operation

Lecture 73 TURN MILL Rough operation

Lecture 74 Rotary_Roughing

Lecture 75 Rotary_Roughing operation

Any Technical students.

Published 9/2024

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 8.94 GB | Duration: 10h 58m

Download

*

Siemens NX CAM Hands-On. Learn how to create toolpath and CNC Program using NX CAM for Beginners.

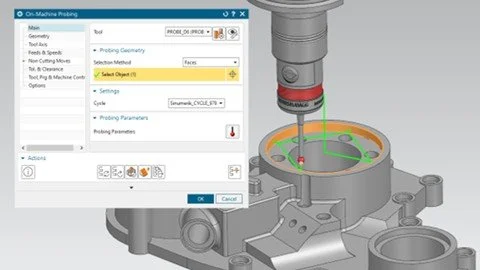

What you'll learn

You will understand CAM concept and advanced manufacturing topics in Siemens NX CAM 2312.

How to import the part file from any CAD software like Solidworks, Solidedge and catia v5.

Work independently on any Part in any version of Siemens NX .

Make any toolpath for any complex part easily using a NX CAM operations as shown in Examples.

Requirements

Any cad course knowledge.

Description

The SIEMENS NX CAM 2312 Basic Manufacturing course will introduce the main concepts of CAM programming using this computer-aided manufacturing tool. It will introduce the student to all the concepts and most importantly tools, the work philosophy within NX CAM 2312. In this course, several 2.5Axis, 3Axis, and 4Axis machining toolpath will be covered, where the student will learn to correctly choose and define their machining strategies, create tools, learn that, with NX 2312,In this course I will cover· Planner milling (generate complete machining processes for prismatic parts of any complexity)· Contour milling (generate high-quality mold inserts using a complete set of advanced NC programming tools.)· Multi axis (generate Advanced 3+2 milling and 5-axis machining methods allow you to produce challenging molds with deep cavities)· Turning (Generate program for 2D part profiles or full solid models roughing, multiple pass finishing, grooving, thread cutting and centerline drilling operations)· HOLE making (Generate program for 2D part or full solid models for Drilling, Spot drilling etc operations)· Features machining (NX CAM 2312 can automate CNC programing by using Feature-Based Machining (FBM)· Multi axis Blade (Generate programming of complex multi-bladed such as blisks and impellers)· Mill rotary (generate programming of complex rotational parts, with specialized 4-axis NC programming operations)· Post processor (Generate NC programs for a wide range of machine tools and controllers using Post builder)

Overview

Section 1: Introduction

Lecture 1 Introduction to NX CAM 2312

Lecture 2 How to import .xt, stp & .prt files

Lecture 3 How to define Blank Geometry for NX CAM

Lecture 4 Manufacturing Assemblies Introduction

Lecture 5 Non cutting Move (Engage & Retract)

Lecture 6 Cutting Parameters (Cut Level)

Lecture 7 Cutting Parameters 2

Lecture 8 NC Assistant

Lecture 9 How to add tool in tool library

Section 2: NX 2312 Milling Planar Milling (2.5 Axis Operations)

Lecture 10 FaceMill MidPass operation

Lecture 11 Face_Mill_ZigZag Operation

Lecture 12 Floor Facing without wall operation

Lecture 13 Floor and Wall Operation

Lecture 14 Pocket Milling Operation

Lecture 15 2D Profile wall without Floor

Lecture 16 2D Profile Wall with Floor

Lecture 17 Planar profile

Lecture 18 Planar profile

Lecture 19 Planar MIll

Lecture 20 Groove Milling

Lecture 21 Face mill Manual

Lecture 22 Planar Text

Lecture 23 2.5Axis Planar Mill

Section 3: NX 2312 Milling Contour Operations (3 Axis operations)

Lecture 24 Cavity Mill Rough operation

Lecture 25 Cavity Mill

Lecture 26 Cavity Mill

Lecture 27 Cavity Mill

Lecture 28 REST Mill

Lecture 29 Plunge mill Rough operation

Lecture 30 Z LEVEL PROFILE STEEP

Lecture 31 ZLEVEL PROFILE EXERCISE

Lecture 32 ZLevel Corner

Lecture 33 Quick Roughing

Lecture 34 3D Adaptive Roughing milling

Lecture 35 3D Adaptive Roughing milling

Lecture 36 3D Adaptive Roughing milling

Lecture 37 Area Mill Finishing operation

Lecture 38 Area Mill Finishing operation

Lecture 39 Area Mill Finishing operation

Lecture 40 Area Mill Finishing operation

Lecture 41 Fixed Axis Guiding Curve finishing operation

Lecture 42 Fixed Axis Guiding Curve finishing operation

Lecture 43 ZLevel UnderCut

Lecture 44 Flow Cut Drive method

Lecture 45 Curve drive operation

Lecture 46 Solid Profile operation

Lecture 47 Profile 3D operation

Lecture 48 Streamline Finishing operation

Lecture 49 Streamline Finishing operation

Lecture 50 Contour Surface Drive finishing operation

Lecture 51 Contour Surface Drive finishing operation

Lecture 52 contour Text Engraving operation

Lecture 53 3_AXIS_DEBURRING

Lecture 54 Multi setup toolpath (IPW Blank)

Section 4: NX 2312 Milling Cutting Parameters & Non-Cutting Moves

Lecture 55 Non-Cutting Move (Engage & Retract)

Lecture 56 Cutting Parameters (Cut Level)

Lecture 57 Cutting Parameters

Lecture 58 How to Trim toolpath and Divide toolpath

Lecture 59 How to transform toolpath

Lecture 60 Toolpath SUB Options (Toolpath check, Validity Report etc)

Lecture 61 How to create 3Axis post processer

Section 5: Hole machining operations

Lecture 62 Spot Drill & Drilling

Lecture 63 Deep Hole Drilling

Lecture 64 Hole milling

Lecture 65 Boss Milling

Lecture 66 Radial Groove Milling

Lecture 67 Hole chamfer mill

Section 6: NX 2312 Milling 3 Axis Projects

Lecture 68 Project 1

Lecture 69 Project 2

Lecture 70 Project 3

Lecture 71 Project Cavity

Section 7: Rotary MILL (4Axis Milling operations)

Lecture 72 TURN MILL Rough operation

Lecture 73 TURN MILL Rough operation

Lecture 74 Rotary_Roughing

Lecture 75 Rotary_Roughing operation

Any Technical students.

Published 9/2024

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 8.94 GB | Duration: 10h 58m

Download

*