Oil Well Instrumentation And Control Systems

Safety, Monitoring, and Best Practices in Upstream Oil and Gas operation

What you'll learn

Fundamentals of Oil Well Instrumentation – Understanding key instruments like pressure, temperature, flow, and level measurement devices.

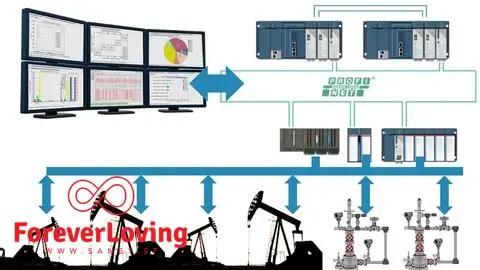

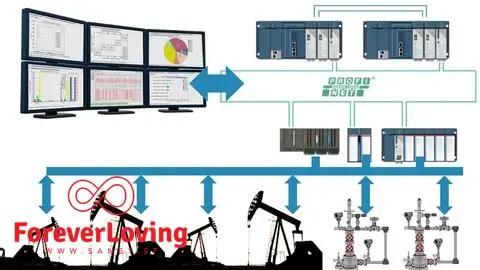

Types of Control Systems – Master the roles of PLC, DCS, and SCADA in automating oil well operations.

Safety Interlocks and Emergency Shutdowns – Learn how safety interlocks and ESD systems prevent accidents and ensure operational safety.

Integration of Sensors and Transmitters – Discover how sensors and transmitters work together for real-time monitoring in oil wells.

Industry Standards and Hazardous Area Classification – Gain insights into key safety regulations and classifications in oil well instrumentation.

Troubleshooting and Maintenance of Oil Well Instruments – Learn practical techniques for troubleshooting common instrumentation issues.

Calibration Techniques for Sensors and Instruments – Understand how to calibrate and maintain instruments for accurate readings and optimal performance.

Requirements

Basic Understanding of Oil and Gas Operations

Basic Understanding of instrumentation and Control

Description

Are you ready to dive into the world of oil well operations and understand how instrumentation and control systems ensure safe, efficient, and productive oil extraction? This course is your gateway to mastering the essential skills needed to monitor, control, and maintain oil well operations—whether you’re a newcomer to the field or looking to expand your knowledge.

Why Enroll in This Course?Oil wells are intricate systems where precision and safety are paramount. Instrumentation and control systems play a critical role in real-time monitoring, automation, and ensuring operational safety. This course provides a comprehensive, practical approach to understanding these systems, with a special focus on safety interlocks, emergency shutdowns, and industry regulations that protect both the environment and human life.

What You Will Learn:

Core Concepts of Oil Well Instrumentation: Get a detailed understanding of pressure, temperature, flow, and level measurement devices used in oil wells.Integration of Control Systems: Learn about the different types of control systems (PLC, DCS, SCADA) and how they are used to automate oil well operations.Safety and Emergency Systems: Gain insights into safety interlocks, emergency shutdown (ESD) systems, and fire and gas detection systems essential for preventing accidents in oil wells.

Industry Standards and Regulations: Understand the key safety standards and hazardous area classifications for oil well instrumentation and control systems.Hands-on Approach to Calibration and Maintenance: Master the techniques of calibrating and maintaining sensors, instruments, and safety systems for optimal performance.

Who Should Take This Course?

Freshers and Newcomers: If you're just entering the field of oil and gas or looking to enhance your foundational knowledge in oil well instrumentation and control systems, this course is perfect for you.Field Engineers and Technicians: Professionals seeking to expand their expertise in instrumentation, control systems, and safety interlocks in oil well operations.Health, Safety, and Environmental (HSE) Professionals: Those interested in understanding how instrumentation and control systems contribute to oil well safety.

Course Highlights:Step-by-Step Learning:

The course is designed to take you from the fundamentals of oil well operations to advanced safety systems.Real-World Case Studies: Learn from practical examples and case studies of successful instrumentation and control implementations in oil wells.Engaging Visual Content: Visual aids, diagrams, and real-world imagery to help reinforce complex concepts.Up-to-Date with Industry Trends: Stay informed on the latest technology and standards in oil well instrumentation and control systems.

Why This Course Stands OutWith 20 years of experience in instrumentation and control engineering, I’ve designed this course to offer both theoretical knowledge and hands-on expertise. You won’t just learn the “what,” but also the “how” and “why” behind every system used in oil well operations.By the end of this course, you will not only understand how to monitor and control oil wells but also how to troubleshoot common issues, ensuring safe and efficient operations.Enroll Now!Take the first step towards mastering oil well instrumentation and control systems. Join now to gain the skills that are in demand across the oil and gas industry!

Overview

Section 1: Introduction

Lecture 1 Introduction to course

Lecture 2 Overview of Oil Well Operations

Lecture 3 Importance of Instrumentation in Oil Well Monitoring

Lecture 4 Key Components of an Oil Well Instrumentation System

Lecture 5 Role of Control Systems in Oil Wells

Lecture 6 Industry Standards and Regulations

Section 2: Field Instrumentation for Oil Well Monitoring

Lecture 7 Pressure Measurement Instruments

Lecture 8 Temperature Measurement Instruments

Lecture 9 Flow Measurement Devices

Lecture 10 Level Measurement Instruments

Lecture 11 Integration of Sensors and Transmitters in Oil Wells

Section 3: Control Systems in Oil Wells

Lecture 12 Overview of Control Systems in the Oil Industry

Lecture 13 Communication Protocols in Oil Well Control Systems

Lecture 14 Data Acquisition and Real-Time Monitoring

Lecture 15 Control Room Interface HMI and Operator Panel

Section 4: Safety Interlocks and Shutdown Systems

Lecture 16 Importance of Safety Interlocks in Oil Wells

Lecture 17 Emergency Shutdown Systems (ESD) for Oil Wells

Lecture 18 Fire and Gas Detection Systems

Lecture 19 Best Practices for Maintaining Safety Systems

Section 5: Safety and Hazard Mitigation in Oil Well Operations

Lecture 20 Safety Standards in Oil Wells

Lecture 21 Hazardous Area Classification and Instrumentation

Lecture 22 Remote Shutdown and Isolation Techniques

Section 6: Oil Well Instrumentation Network Architecture

Lecture 23 Instrumentation and Control System Network Overview

Lecture 24 Wiring and Cabling Best Practices in Oil Wells

Lecture 25 Redundancy and Fail-Safe Design

Lecture 26 Remote Monitoring and Control via SCADA Systems

Section 7: Maintenance and Troubleshooting of Oil Well Instrumentation

Lecture 27 Routine Maintenance Procedures

Lecture 28 Troubleshooting Common Instrumentation Issues

Engineering or technical students who want to learn about the practical applications of instrumentation and control in oil well operations.,Instrumentation Engineers,Instrumentation Technicians,Automation and Control System Enthusiasts

Published 10/2024

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 545 MB | Duration: 1h 4m

Download

*

Safety, Monitoring, and Best Practices in Upstream Oil and Gas operation

What you'll learn

Fundamentals of Oil Well Instrumentation – Understanding key instruments like pressure, temperature, flow, and level measurement devices.

Types of Control Systems – Master the roles of PLC, DCS, and SCADA in automating oil well operations.

Safety Interlocks and Emergency Shutdowns – Learn how safety interlocks and ESD systems prevent accidents and ensure operational safety.

Integration of Sensors and Transmitters – Discover how sensors and transmitters work together for real-time monitoring in oil wells.

Industry Standards and Hazardous Area Classification – Gain insights into key safety regulations and classifications in oil well instrumentation.

Troubleshooting and Maintenance of Oil Well Instruments – Learn practical techniques for troubleshooting common instrumentation issues.

Calibration Techniques for Sensors and Instruments – Understand how to calibrate and maintain instruments for accurate readings and optimal performance.

Requirements

Basic Understanding of Oil and Gas Operations

Basic Understanding of instrumentation and Control

Description

Are you ready to dive into the world of oil well operations and understand how instrumentation and control systems ensure safe, efficient, and productive oil extraction? This course is your gateway to mastering the essential skills needed to monitor, control, and maintain oil well operations—whether you’re a newcomer to the field or looking to expand your knowledge.

Why Enroll in This Course?Oil wells are intricate systems where precision and safety are paramount. Instrumentation and control systems play a critical role in real-time monitoring, automation, and ensuring operational safety. This course provides a comprehensive, practical approach to understanding these systems, with a special focus on safety interlocks, emergency shutdowns, and industry regulations that protect both the environment and human life.

What You Will Learn:

Core Concepts of Oil Well Instrumentation: Get a detailed understanding of pressure, temperature, flow, and level measurement devices used in oil wells.Integration of Control Systems: Learn about the different types of control systems (PLC, DCS, SCADA) and how they are used to automate oil well operations.Safety and Emergency Systems: Gain insights into safety interlocks, emergency shutdown (ESD) systems, and fire and gas detection systems essential for preventing accidents in oil wells.

Industry Standards and Regulations: Understand the key safety standards and hazardous area classifications for oil well instrumentation and control systems.Hands-on Approach to Calibration and Maintenance: Master the techniques of calibrating and maintaining sensors, instruments, and safety systems for optimal performance.

Who Should Take This Course?

Freshers and Newcomers: If you're just entering the field of oil and gas or looking to enhance your foundational knowledge in oil well instrumentation and control systems, this course is perfect for you.Field Engineers and Technicians: Professionals seeking to expand their expertise in instrumentation, control systems, and safety interlocks in oil well operations.Health, Safety, and Environmental (HSE) Professionals: Those interested in understanding how instrumentation and control systems contribute to oil well safety.

Course Highlights:Step-by-Step Learning:

The course is designed to take you from the fundamentals of oil well operations to advanced safety systems.Real-World Case Studies: Learn from practical examples and case studies of successful instrumentation and control implementations in oil wells.Engaging Visual Content: Visual aids, diagrams, and real-world imagery to help reinforce complex concepts.Up-to-Date with Industry Trends: Stay informed on the latest technology and standards in oil well instrumentation and control systems.

Why This Course Stands OutWith 20 years of experience in instrumentation and control engineering, I’ve designed this course to offer both theoretical knowledge and hands-on expertise. You won’t just learn the “what,” but also the “how” and “why” behind every system used in oil well operations.By the end of this course, you will not only understand how to monitor and control oil wells but also how to troubleshoot common issues, ensuring safe and efficient operations.Enroll Now!Take the first step towards mastering oil well instrumentation and control systems. Join now to gain the skills that are in demand across the oil and gas industry!

Overview

Section 1: Introduction

Lecture 1 Introduction to course

Lecture 2 Overview of Oil Well Operations

Lecture 3 Importance of Instrumentation in Oil Well Monitoring

Lecture 4 Key Components of an Oil Well Instrumentation System

Lecture 5 Role of Control Systems in Oil Wells

Lecture 6 Industry Standards and Regulations

Section 2: Field Instrumentation for Oil Well Monitoring

Lecture 7 Pressure Measurement Instruments

Lecture 8 Temperature Measurement Instruments

Lecture 9 Flow Measurement Devices

Lecture 10 Level Measurement Instruments

Lecture 11 Integration of Sensors and Transmitters in Oil Wells

Section 3: Control Systems in Oil Wells

Lecture 12 Overview of Control Systems in the Oil Industry

Lecture 13 Communication Protocols in Oil Well Control Systems

Lecture 14 Data Acquisition and Real-Time Monitoring

Lecture 15 Control Room Interface HMI and Operator Panel

Section 4: Safety Interlocks and Shutdown Systems

Lecture 16 Importance of Safety Interlocks in Oil Wells

Lecture 17 Emergency Shutdown Systems (ESD) for Oil Wells

Lecture 18 Fire and Gas Detection Systems

Lecture 19 Best Practices for Maintaining Safety Systems

Section 5: Safety and Hazard Mitigation in Oil Well Operations

Lecture 20 Safety Standards in Oil Wells

Lecture 21 Hazardous Area Classification and Instrumentation

Lecture 22 Remote Shutdown and Isolation Techniques

Section 6: Oil Well Instrumentation Network Architecture

Lecture 23 Instrumentation and Control System Network Overview

Lecture 24 Wiring and Cabling Best Practices in Oil Wells

Lecture 25 Redundancy and Fail-Safe Design

Lecture 26 Remote Monitoring and Control via SCADA Systems

Section 7: Maintenance and Troubleshooting of Oil Well Instrumentation

Lecture 27 Routine Maintenance Procedures

Lecture 28 Troubleshooting Common Instrumentation Issues

Engineering or technical students who want to learn about the practical applications of instrumentation and control in oil well operations.,Instrumentation Engineers,Instrumentation Technicians,Automation and Control System Enthusiasts

Published 10/2024

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 545 MB | Duration: 1h 4m

Download

*