Gear And Gear Trains: Theory And Design Concepts

Fundamentals of Gear Design,Gear Kinematics and Dynamics,Gear Train Systems, Interference in involute gears

What you'll learn

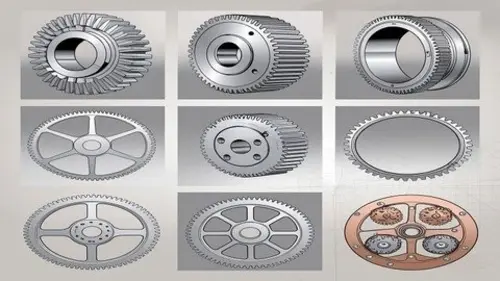

Exploring the fundamental concepts of gears and gear trains, including their classification, working principles, and applications in mechanical systems.

Analyze the kinematics and dynamics of different types of gears (e.g., spur, helical, bevel, and worm gears) and gear trains

Apply theoretical knowledge and design methodologies to create efficient and reliable gear and gear train systems for various engineering applications.

Solve Practical Engineering Problems based on gear and gear trains by analyzing the different terms such as module, pitch circle diameter, circular pitch etc

Requirements

Basic Knowledge of Mechanics, engineering mathematics. Not mandatory

Description

The course Gear and Gear Trains: Theory and Design Concepts is designed to provide a comprehensive understanding of the principles, analysis, and design of gears and gear train systems. This course covers the fundamental concepts of gear geometry, classification, and tooth profiles, focusing on the Law of Gearing, which ensures smooth and uniform power transmission. Course helps to explore various types of gears, including spur, helical, bevel, and worm gears, and analyze their working principles, applications, and performance in mechanical systems. It helps in the understanding of the various terminologies that are important for gear design such as module, pitch circle, circular pitch, concept of length of the path of contact, length of the arc of contact etc. It also enables the understanding of tooth profiles i.e. cycloid and involute profiles , their comparison and systems of gear teeth that generally used in sectors i.e automobile, aerospace and other manufacturing sectors. Furthermore, course also focus on design and analysis of gear trains, such as simple, compound, reverted and epicyclic systems, used in diverse engineering applications. How to calculate the speed ratio or train value during power transmission from driver to driven gear. Importance of idle or intermediate gears during power transmission.

Overview

Section 1: Introduction

Lecture 1 Introduction: Gears/ Toothed Wheels

Lecture 2 Classification of Gears or Toothed Wheels

Section 2: Terminologies used in Gears

Lecture 3 Terminologies used in Gears

Section 3: Law of Gearing and Velocity of sliding of Teeth

Lecture 4 Law of Gearing

Lecture 5 Velocity of sliding of Teeth

Section 4: Types of Teeth

Lecture 6 Types of Teeth

Lecture 7 Effect of Altering the Centre Distance on Velocity Ratio for Involute Teeth

Lecture 8 Comparison Between Involute and Cycloidal Gears

Lecture 9 Systems of Gear Teeth

Lecture 10 Length of Path of Contact

Lecture 11 Length of arc of contact

Section 5: Interference in Involute Gears

Lecture 12 Interference in Involute Gears

Lecture 13 Minimum Number of Teeth on the Pinion in Order to Avoid interference

Lecture 14 Minimum Number of Teeth on the Wheel in Order to Avoid interference

Lecture 15 Minimum Number of Teeth on a Pinion for Involute Rack to avoid interference

Section 6: Gear Trains

Lecture 16 Introduction Gear Trains

Lecture 17 Simple Gear Train

Lecture 18 Compound Gear Train

Lecture 19 Reverted Gear Train

Lecture 20 Epicyclic Gear Train

Lecture 21 Numerical Problem: Epicyclic gear train

Undergraduate and graduate students pursuing degrees in mechanical engineering, automotive engineering, robotics, or related fields, who want to deepen their understanding of gear mechanics and design.,Professionals in Mechanical Engineering

Published 12/2024

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 1.25 GB | Duration: 4h 33m

Download

*

Fundamentals of Gear Design,Gear Kinematics and Dynamics,Gear Train Systems, Interference in involute gears

What you'll learn

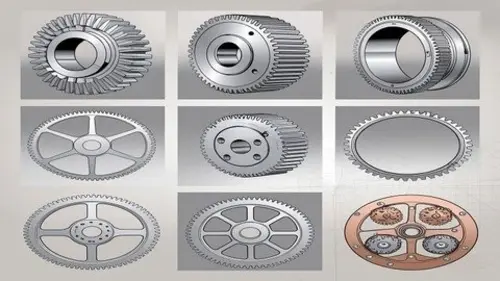

Exploring the fundamental concepts of gears and gear trains, including their classification, working principles, and applications in mechanical systems.

Analyze the kinematics and dynamics of different types of gears (e.g., spur, helical, bevel, and worm gears) and gear trains

Apply theoretical knowledge and design methodologies to create efficient and reliable gear and gear train systems for various engineering applications.

Solve Practical Engineering Problems based on gear and gear trains by analyzing the different terms such as module, pitch circle diameter, circular pitch etc

Requirements

Basic Knowledge of Mechanics, engineering mathematics. Not mandatory

Description

The course Gear and Gear Trains: Theory and Design Concepts is designed to provide a comprehensive understanding of the principles, analysis, and design of gears and gear train systems. This course covers the fundamental concepts of gear geometry, classification, and tooth profiles, focusing on the Law of Gearing, which ensures smooth and uniform power transmission. Course helps to explore various types of gears, including spur, helical, bevel, and worm gears, and analyze their working principles, applications, and performance in mechanical systems. It helps in the understanding of the various terminologies that are important for gear design such as module, pitch circle, circular pitch, concept of length of the path of contact, length of the arc of contact etc. It also enables the understanding of tooth profiles i.e. cycloid and involute profiles , their comparison and systems of gear teeth that generally used in sectors i.e automobile, aerospace and other manufacturing sectors. Furthermore, course also focus on design and analysis of gear trains, such as simple, compound, reverted and epicyclic systems, used in diverse engineering applications. How to calculate the speed ratio or train value during power transmission from driver to driven gear. Importance of idle or intermediate gears during power transmission.

Overview

Section 1: Introduction

Lecture 1 Introduction: Gears/ Toothed Wheels

Lecture 2 Classification of Gears or Toothed Wheels

Section 2: Terminologies used in Gears

Lecture 3 Terminologies used in Gears

Section 3: Law of Gearing and Velocity of sliding of Teeth

Lecture 4 Law of Gearing

Lecture 5 Velocity of sliding of Teeth

Section 4: Types of Teeth

Lecture 6 Types of Teeth

Lecture 7 Effect of Altering the Centre Distance on Velocity Ratio for Involute Teeth

Lecture 8 Comparison Between Involute and Cycloidal Gears

Lecture 9 Systems of Gear Teeth

Lecture 10 Length of Path of Contact

Lecture 11 Length of arc of contact

Section 5: Interference in Involute Gears

Lecture 12 Interference in Involute Gears

Lecture 13 Minimum Number of Teeth on the Pinion in Order to Avoid interference

Lecture 14 Minimum Number of Teeth on the Wheel in Order to Avoid interference

Lecture 15 Minimum Number of Teeth on a Pinion for Involute Rack to avoid interference

Section 6: Gear Trains

Lecture 16 Introduction Gear Trains

Lecture 17 Simple Gear Train

Lecture 18 Compound Gear Train

Lecture 19 Reverted Gear Train

Lecture 20 Epicyclic Gear Train

Lecture 21 Numerical Problem: Epicyclic gear train

Undergraduate and graduate students pursuing degrees in mechanical engineering, automotive engineering, robotics, or related fields, who want to deepen their understanding of gear mechanics and design.,Professionals in Mechanical Engineering

Published 12/2024

MP4 | Video: h264, 1920x1080 | Audio: AAC, 44.1 KHz

Language: English | Size: 1.25 GB | Duration: 4h 33m

Download

*